Infrared Microscope

Microscope Thermography

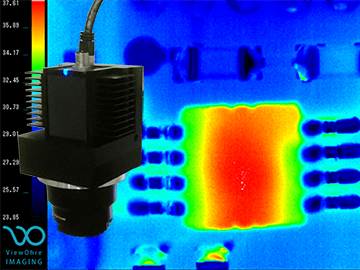

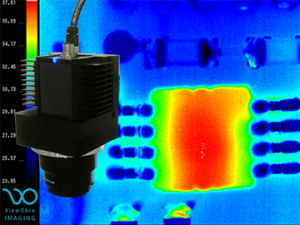

By the quality of the lens, alter the thermal image.

By choosing lens, convert the purpose.

Measurement in the microscale domain, microscope x ThermalViewX

Development background and consept

Points of the development

✓ Even in a 1mm² area indicating an average of 100°C, there may be areas where it reaches 400°C locally due to distribution.

✓ In the field of advanced semiconductor research, precise measurements with high accuracy, tailored to the area and as finely detailed as possible, are crucial.

✓ ThermalViewX MCR Series realize the high resolution, proprietary correction, and specialized calibration.

✓ Select the camera (pixels, speed, wave length) for your purpose and costs.

✓ Select the App software with essential and unique functions tailored for microscope purposes.

✓ Using easy-to-use ThermalViewX applications.

✓ Designing the app with scalability to accommodate future changes in usage.

✓ Achieving measurements that are not achievable with regular thermographis or cameras that have not undergone specialized calibration.

Features

✓ Achieves a resolution of less than 10 μm (from 8.7 μm to 7.9 μm) with non-cooled models.

✓ Achieves a resolution of 3 μm with cooled models.

✓ Performs unique correction and calibration for microscopy applications.

✓ Includes essential features as standard, such as video measurement, temperature value display on the GUI, zoom functionality, CSV output, and AVI output.

✓ Offers various extended functions, including video analysis, differential measurement, differential evaluation, and statistical analysis.

✓ Wide lineup. From cost-effective to high-end, high-resolution versions.

✓ Real-time Display, Easy operation with mouse click, Easy check of measured temperature with mouseover

✓ Does not miss small changes.

✓ Utilizes the integrated software "ThermalViewX Platform."

✓ The top-tier model can use CSV-simulated data and temperature values from other companies' cameras as reference data for differential measurements.

Main feature of the MCR series

Installed specialized calibration and correction function for measurement in the microscale domain

Make applications extensible to measurement in the microscale domain from resolutions below 10μm to 100μm.

Real-time display. Movie shooting.

Specialized measurement function for organisms

Production Information

High resolution at a low price Ⅰ Cooling-based high-end

TYPE S ・ R ・ D ・ SC

These are microscope thermography systems that achieve high sensitivity while maintaining a low cost. Typically, acquiring micron-level thermal images requires expensive infrared microscope systems. However, ThermalViewX MCR-XA0350 and XA0657 have achieved a balance between cost reduction and the sensitivity required for microscopy applications, making them suitable for focused applications such as temperature distribution measurement and use near room temperature.